Accueil » Our services »

Structural mechanics and experimental approach

DESIGN ROBUST AND HIGH RELIABLE PARTS

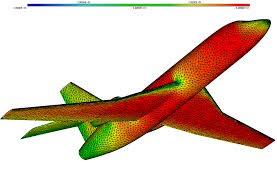

The design of a mechanical part can be done efficiently today with the use of finite element method. This numerical approach of structural mechanics use discretization of the entire part to look at areas with high mechanical stresses in order to design against catastrophic failures.

WHICH MATERIALS TO USE ?

Mechanical properties of a material is characterized by different parameters.

like the tensile strength … etc

Young’s modulus and elongation at failure are also essential parameters and designers are unable to predict robust structures without those informations.

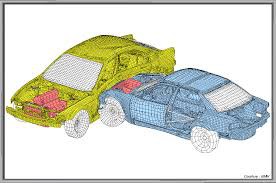

Designing of a simple ladder or a more complexbmechanical structure such as airplanes or cars , it will be mandatory to know those different parameters on the material used to manufacture the part – It is then possible to verify if the material used complies with the technical specifications.

Expert in Numerical Calculation

Atalolo B. Dagba,

USA

Holder of numerous scientific publications and patents. Mr. A. Dagba is a world reference in the field of numerical approaches to Crash analysis.

Some references of his works:

US patent 7093886 B2 Aug 22, 2006 Vehicle door beam with reinforced tab and method for making the same.

PUBLICATIONS

- Numerical techniques, experimental validations and industrial applications of structural impact and crashworthiness analysis with supercomputers for the automotive industries (Zurich 1986) (Proceedings of the International Conference on Supercomputer Applications in the automotive industry). Chedmail and Al, E. Haug, A. Dagba

- Industrial simulations using the PAMCRASH code (Supercomputing in engineering structures Computational mechanics 1989).

E. Haug, A. Dagba, J. Clinckemaillie, F. Aberlenc